We “Baby Boomers” had parents that were raised during the depths of the depression, fought in World War Two and deservedly earned the title of “The Greatest Generation.” By comparison to them, we “boomers” had it easy. One notable advantage that we had over our parents was easy access during our impressionable years to the finest gun writers in the history of sporting journalism. Ask any “boomer” gun nut who their favorite gun scribes were when they were growing up and the list will certainly contain Elmer Keith, Bill Jordan and Skeeter Skelton, revolver devotees, all. Those scribes led some of us down the road from mere interest, to obsession, to near-fixation with guns and shooting at an early age.

Until the late 1970’s and the rapid growth of IPSC, revolvers dominated the handgun culture here in the United States, and most of us “boomers” cut our teeth shooting revolvers. As the sport of practical shooting mushroomed, semi autos in general and the 1911 in specific, started to cut in-roads into the popularity of revolvers. Add to that the importation of high quality, functional and innovative semi-automatic handguns from Europe, and a major shift in handgun enthusiasm commenced. In 1986 the Glock 17 hit our shores followed in 1988 by the Glock 19. Up until that time, police departments that didn’t issue revolvers were as scarce as a Kardashian at a tractor-pull; now, the opposite is true. While the revolver collector market continued to thrive, the market for new double action revolvers declined.

I can’t explain exactly when or why it happened but wheel guns are in the midst of a rebirth of popularity. My friend Ken Hackathorn has said that we’re experiencing a “revolver renaissance,” and I agree with him. In 2017, Colt reintroduced the Colt Cobra, followed in 2019 by the King Cobra, the Python in 2020, the Anaconda in 2021 and the .22 King Cobra in 2022. Whether their reintroduction of these models is the cause or effect of the renewed enthusiasm for revolvers, I don’t know, but I am grateful for the reinvigoration.

A couple of months ago, I was shooting with my friend Matt Olivier and he mentioned that he had attended a media event at Gunsite where a unique revolver was debuted by Finks Custom Gunsmithing. Dave Fink and his cadre of gunsmiths serve as the on-site gunsmithy for the school, repairing student’s guns as well as building some of the finest custom firearms available. The revolver that was being displayed had interchangeable barrels with a unique method of alteration.

Swapping barrels on revolvers is not a contemporary concept. In the 70’s and 80’s, it was not uncommon to see pistol smiths like Bill Davis and Reeves Jungkind, fit Colt Python barrels onto S&W and/or Ruger actions. The resultant “Smolts/Smythons” and “Cougars” were primarily PPC guns as competitors felt that the faster 1:14 twist of the Python’s barrels shot tighter groups than the slower 1:18 3/4 twist of the Smith and Ruger barrels.

Dan Wesson brought do-it-yourself barrel swapping to the handgun market in 1970 which coincided nicely with the rapid growth of metallic silhouette shooting. With practice a competitor could, within a minute, swap barrel lengths of 2 1/2” to 15” on their handgun. Dan Wesson no longer manufactures revolvers which has left a void in the marketplace for those that value the concept of altering their own handgun.

One such customer approached Dave Fink and asked him to build a gun with a similar system to the Dan Wesson. Dave accepted the request as a challenge and recruited the assistance of his best revolver smith, Jake Moreno. According to Dave, Jake took the bull by the horns and came up with some prototypes that evolved into the “Moreno Interchangeable Barrel System” or MIBS. Unlike the Dan Wesson models, the MIBS guns have no barrel shroud or locking nut. They require neither a multi-tool nor a feeler gauge to accomplish the barrel swap.

The MIBS modification is more easily (and clearly) observed than described. There is a rectangular “button” that sticks up on the front end of the top strap of the action. This button is spring loaded and is attached to a short rod that sticks out in the front of the action and fits into a spherical cavity that is cut into the back of the barrel rib, locking the barrel in place. When pulled to the rear, the “button” pulls the rod out of the cavity allowing the barrel to be manually unscrewed and removed from the frame. Conversely, attaching a barrel is a matter of manually screwing on the new barrel while holding the button to the rear. When it’s fully screwed in, release the button and the spring-loaded rod goes forward and fits into the cavity in the back of the barrel rib locking it in place. Adjustable sights sit high enough on the top strap that the “button” isn’t visible in the sight picture. While simple in concept, timing the lock up of the barrel requires precision craftsmanship to accomplish. These guns are “fitted” not “assembled.”

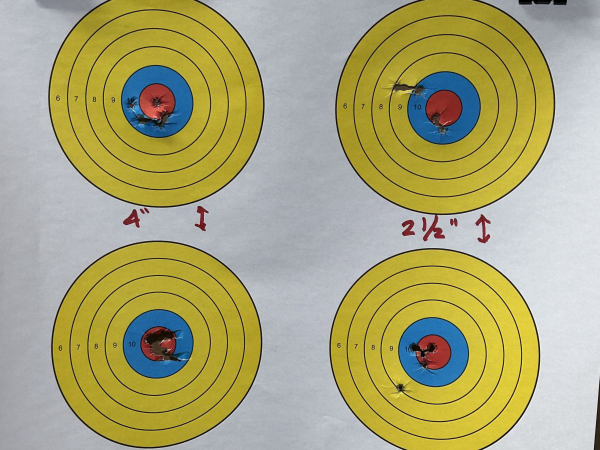

When building a MIBS gun, the individual barrels that the customer selects are mounted on the frame and a barrel-cylinder gap of 4 to 6 thousandths is set depending upon the ammunition that the customer is using. They then recut the forcing cone, crown each barrel and set the timing of the barrel fit for lockup; this ensures that each barrel/action combination has been accurized. They then install the front sights that the customer wants, and do an action job and zero each barrel. Their action job involves polishing the internals and replacing the mainspring and rebound slide spring with an objective of having an 8-pound double action trigger pull without stacking. Test targets are fired to insure both accuracy and that each individual barrel shoots to the same point of impact. The guns are tested from a Ransom Rest at 15 yards; according to Dave, they have yet to have one shoot over 3/4” and most are 1/2” or less.

For revolvers with short ejector rods, an additional detent-lock is put on the yoke which locks into the bottom of the barrel. This is necessary since the rod is too short to lock into the forward locking bolt on longer barrels.

The gun that I tested is a S&W 686-6 Plus that left the factory with a 2 1/2” barrel and now has an additional 4” barrel. The double action trigger pull on this gun drops the hammer an ounce over 8 pounds without any noticeable stacking. While my trifocal bespectacled eyes impede my ability to shoot Ransom-Rest-worthy-groups, my results were above average for me. Of note, shooting consecutive groups with both barrels showed no shift in Point of Impact which was an initial concern of mine.

A secondary concern I had was regarding the durability; specifically, I questioned whether the system might shoot loose, especially with a steady diet of +P ammunition. Dave said that their initial beta testing involved an independent party shooting 1000 rounds utilizing multiple barrels. The test gun held its initial accuracy and the barrel-cylinder gap didn’t change from its original setting. Based upon that trial they were satisfied with both the quality and durability of the system and geared up to produce custom ordered guns. Dave built guns for two customers that live in Alaska; one in .44 Magnum and one .454 Casull. They each ordered a long barrel to be carried in a chest rig for field work with an additional 2 1/2” barrel that they could put on the gun and stick in their waist band when they go into town. To date there have been no issues.

The basic MIBS modification runs $395.00. Extra barrels are procured from various sources such as J&G Sales, Numrich Gun Parts, Apex Gun Parts, Jack First Gun Parts and even eBay so prices for extra barrels vary due to availability. The alteration is currently available on K, L and N frame Smiths. When considering the options of multiple barrel lengths either ported or non-ported and numerous front sight configurations, the combinations are as profuse as preferred gender pronouns at a college campus protest. They may not qualify as “bespoke” but they’re as close as you can come to it in the handgun arena.

For options, availability, and pricing contact Finks Custom Gunsmithing at (928) 756-8916 or finksguns@gmail.com .

— Greg Moats